The ‘invisible hand’ behind human waste disposal

It is common for rural households in developing countries to replace filled-up pits with new ones. However, in emerging towns and cities, covering an old pit to move to another is not an option. Densely populated urban settlements, such as in Tanzania, simply don’t have the space to keep on building new toilets. Emptying services – mechanised, semi-mechanised, or manual – are therefore starting to gain traction as a vital part of the sanitation service chain.

As more people turn to emptying services, demand for sanitation workers (emptiers) is on the rise. SNV’s commitment to improving health and quality of life is not exclusively focused on consumers. For WASH, the welfare and occupational health and safety (OHS) of emptiers are an integral part of SNV’s work. Under the WASH SDG programme, and with the local government of Arusha city and Shinyanga municipality, and the Urban Water Supply and Sanitation Authorities, SNV’s urban sanitation approach is informing improvements in emptiers’ working conditions.

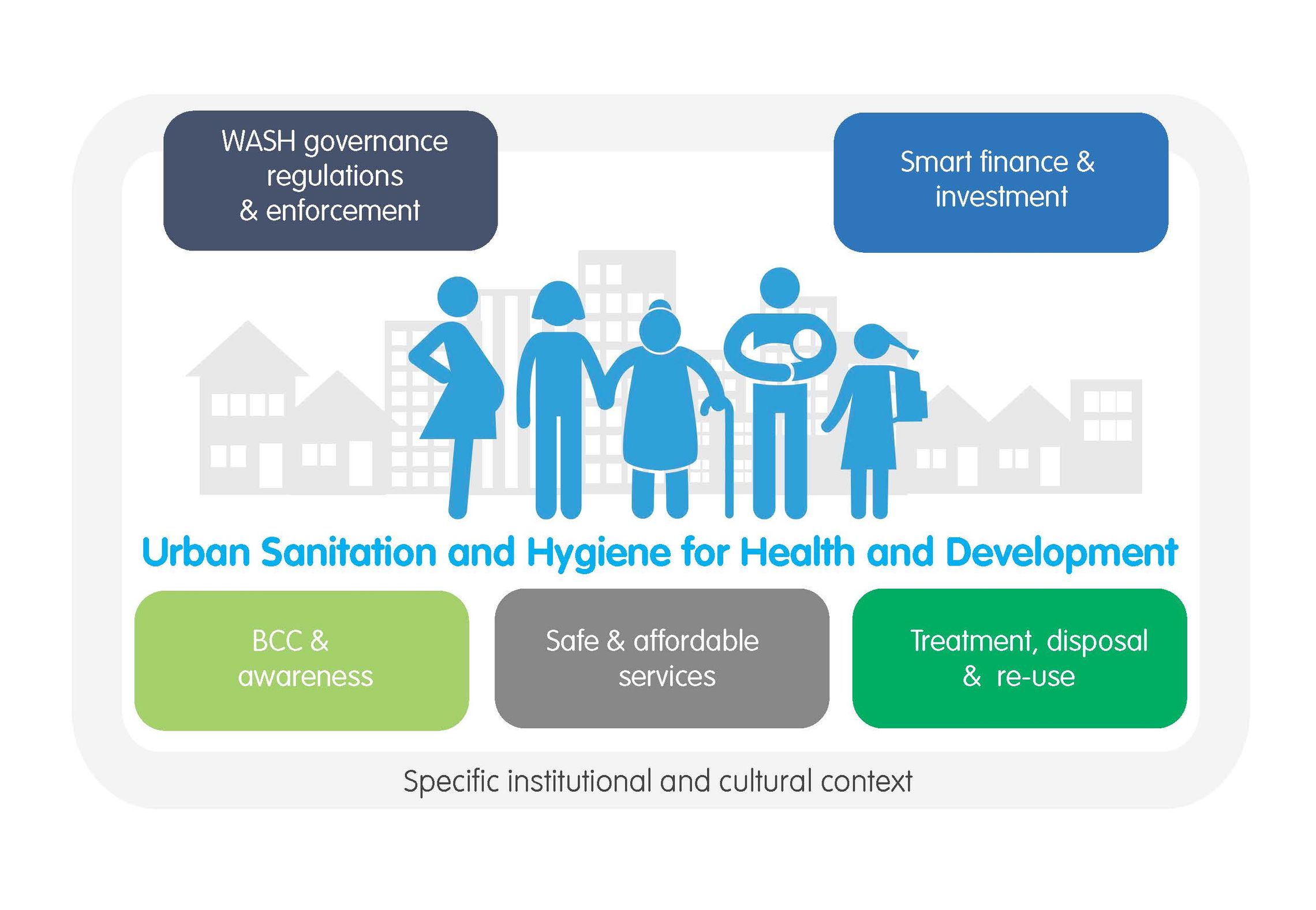

USHHD approach in brief

From Monday, October 29 to Thursday, November 8 2018, in Kandi, 10 masons and supervisors from different regions of Benin were trained in promotion and construction techniques for the domestic bio-digesters model - Faso Bio-15 volume 4m³.

Formative research on OHS/ PPE

Approximately 15 service providers (private and public), including over 35 vacuum trucks, fulfil the emptying needs of Arusha and Shinyanga. In the emptying business, manual and mechanical emptiers often overlook the importance of Occupation Health and Safety (OHS). Despite the health risks associated with unsafe practice, the use of Personal Protective Equipment (PPE) – even when available – is hardly practised.

To understand the motives and barriers behind poor OHS compliance and enforcement, the WASH SDG programme carried out a formative research on OHS and PPE in Arusha and Shinyanga for the period of October 2018 to February 2019. The research explored the behavioural determinants/ barriers to increase emptiers’ PPE uptake, and the approaches/methods used by business operators (e.g., truck operators) to motivate and enforce OHS standards. Research findings are expected to shed light into the development of more effective strategies to institutionalise safe emptying practices, and professionalise the work of emptiers.

Early findings

Poor OHS enforcement and PPE uptake are largely explained by employer and staff negligence; user-unfriendly equipment; a belief that PPEs are not necessary (workers hardly make the link between diseases/ accidents and PPE non-use); and lack of information/ knowledge on PPE benefits (and national OHS laws).

8 of 10 emptiers do not comply with basic OHS measures in Arusha City and Shinyanga municipality.

Although the health risks associated with unsafe emptying operations, e.g., cholera, UTI and skin diseases, are well known – this awareness has yet to be translated to practice. At the time of the research:

89% of all workers did not use PPEs while emptying and disposing of faecal sludge.

Low quality PPEs were used since the purchase of PPEs fell on emptiers. Whilst several business owners claimed to have been promoting PPE use, often emptiers had to buy hand gloves, rain boots, and masks out of their own pockets.

For the few who were using PPEs – these were mainly limited to hand gloves.

Handwashing with soap after emptying was close to nonexistent. After emptying, only one emptier was observed to wash their hands with soap and water.

None of the emptiers was found to be wearing proper uniform or overalls/ overcoats while working.

Also, whilst sanctions for PPE non-compliance were present in some businesses – e.g., salary deductions, temporary suspensions, and other penalties and fines – enforcement was lacklustre due to the absence of evidence or clear procedures. The incentives and means to track OHS compliance in the workplace were missing.

Truck and soak pit emptying

Different workers' gloves in focus*

Safe emptying service and a healthy workforce go hand in hand!

Clearly, the challenges to proper OHS enforcement and PPE uptake are both institutional and attitudinal. To help address these challenges, SNV’s inclusive urban sanitation approach in Tanzania will undertake the following.

At institutional level: To realise systems change in unsafe emptying practice, SNV will contribute to EWURA’s development of the country’s OHS guidelines for emptying services. Part of this commitment includes SNV’s support in strengthening the capacity of responsible authorities – through knowledge skills training and capacity building – to enforce existing policies, laws and regulations relevant to emptying, OHS and PPE use. Emptying operators will be encouraged to register with the Occupational Safety and Health Authority (OSHA). And, the formalisation and legalisation of manual emptiers’ profession will be sought.

At individual level: As emptiers’ work increasingly become professionalised, uptake of PPEs is expected to spike. Behavioural change communication (BCC) campaigns will be undertaken to ensure that positive hygiene behaviour becomes the norm. Similarly, emptiers will also be mobilised for knowledge skills training and capacity building.

Written by Elisekile Mbwille, Business Development Advisor, SNV in Tanzania

*Different workers' gloves in focus: Different types of protective gloves were observed during the research; but none worked optimally. On left, black gloves, short and made of plastic, were found to be uncomfortable (too tight) and the least effective in that it led to excessive sweating (for users), and were prone to fungi growth. On the other hand, whilst the gloves in the centre (burgundy) had a user-friendly cotton interior, and a good length for protection, many were found to have tears. Finally, with its cotton interior, and ribbed exterior (preventing gloves from sliding off while in use), the orange gloves were consider a good option. However due to its short length, it also failed to protect workers from contamination.