Booming Biogas Business

An interview with Bert van Nieuwenhuizen, chief technical advisor on shaping biogas markets in Africa.

This interview comes in two episodes; part one focuses on the fine art of building viable biogas markets, part two will explore the value of biogas in relation to climate change and food security.

What is a bio-digester?

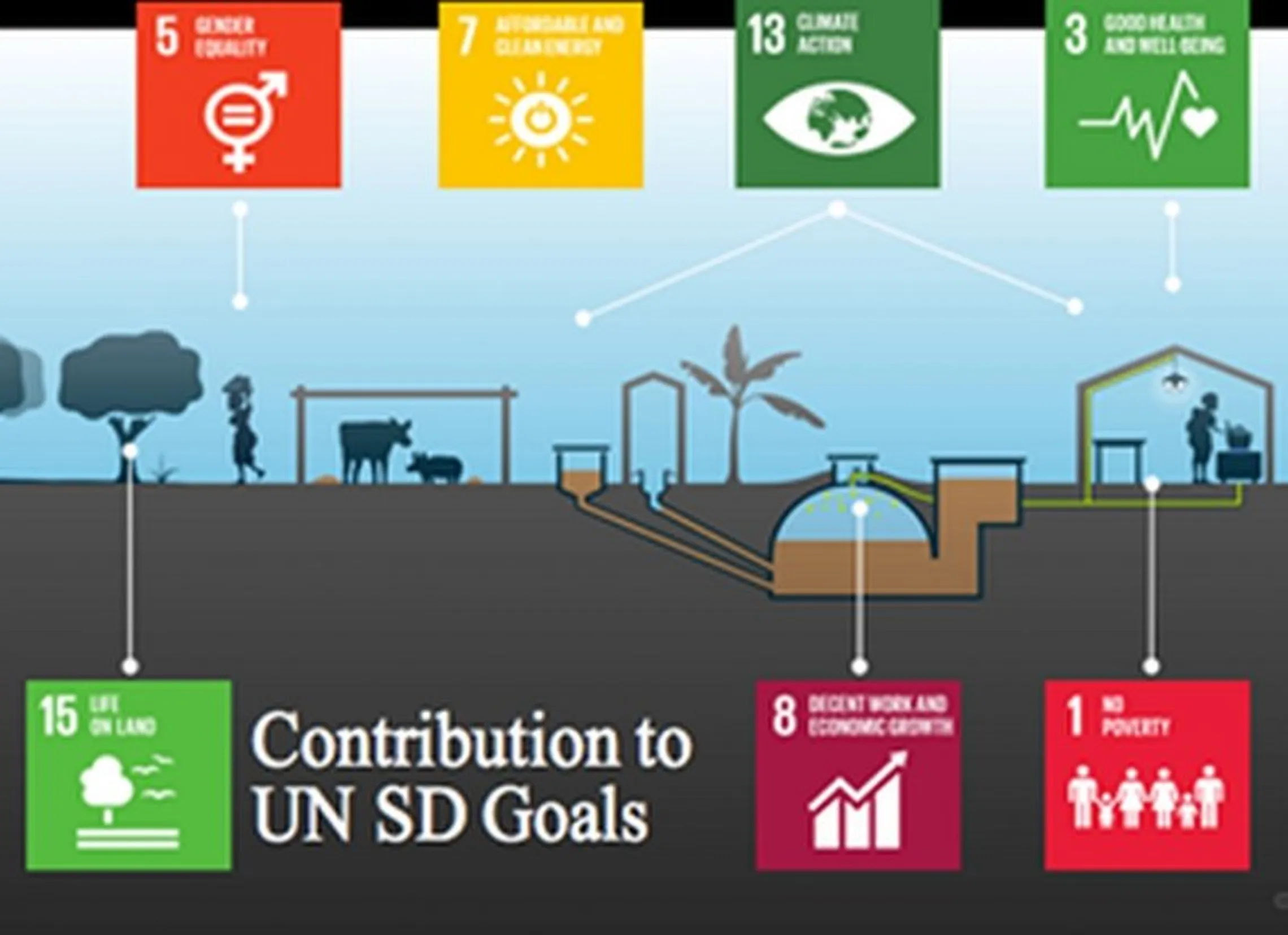

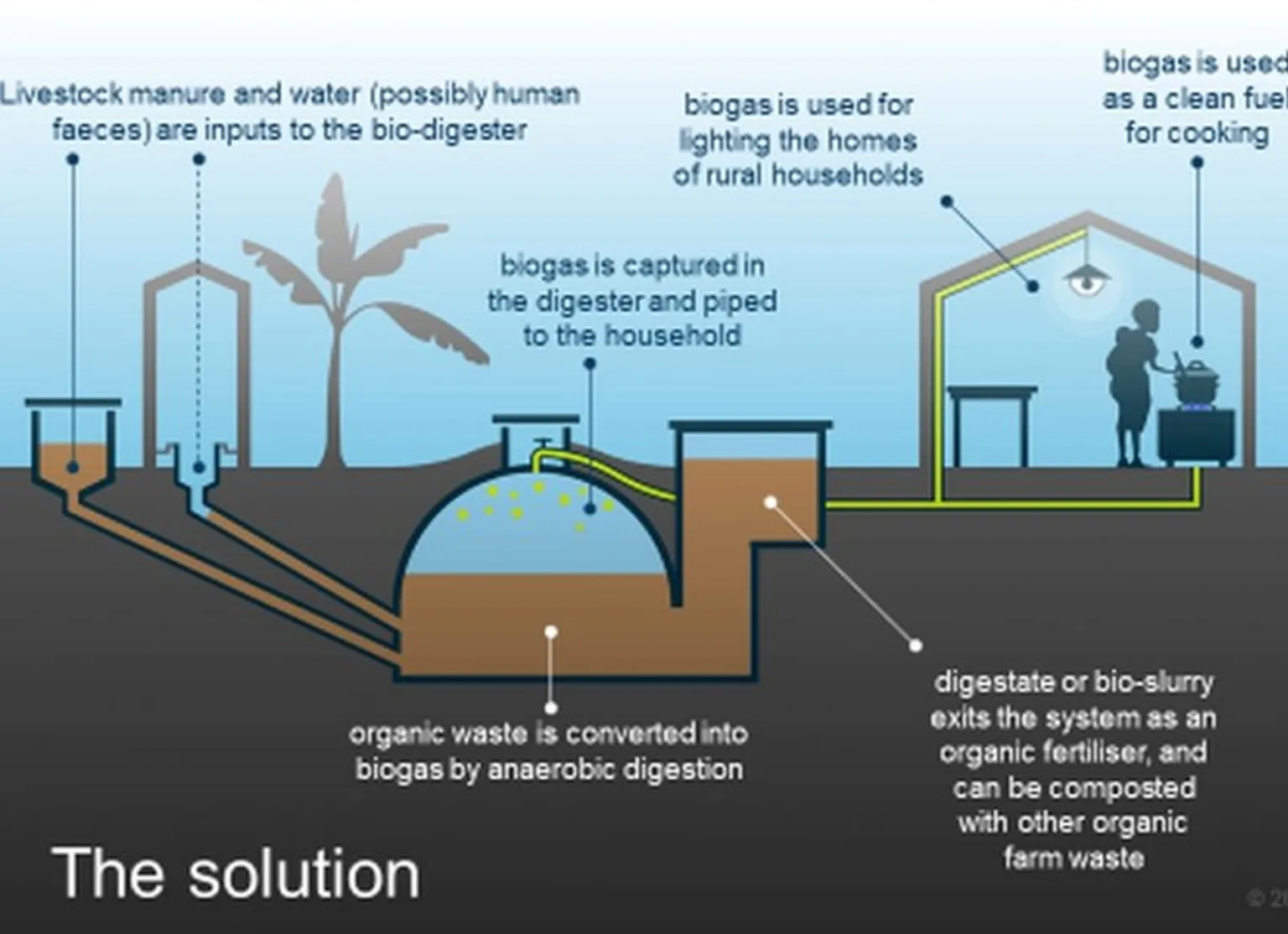

Bio-digesters essentially convert organic waste into combustible methane. Households with just three cows or seven pigs can generate sufficient gas to meet their basic domestic and/or productive energy needs: clean cooking/heating and basic lighting.

How biogas is made

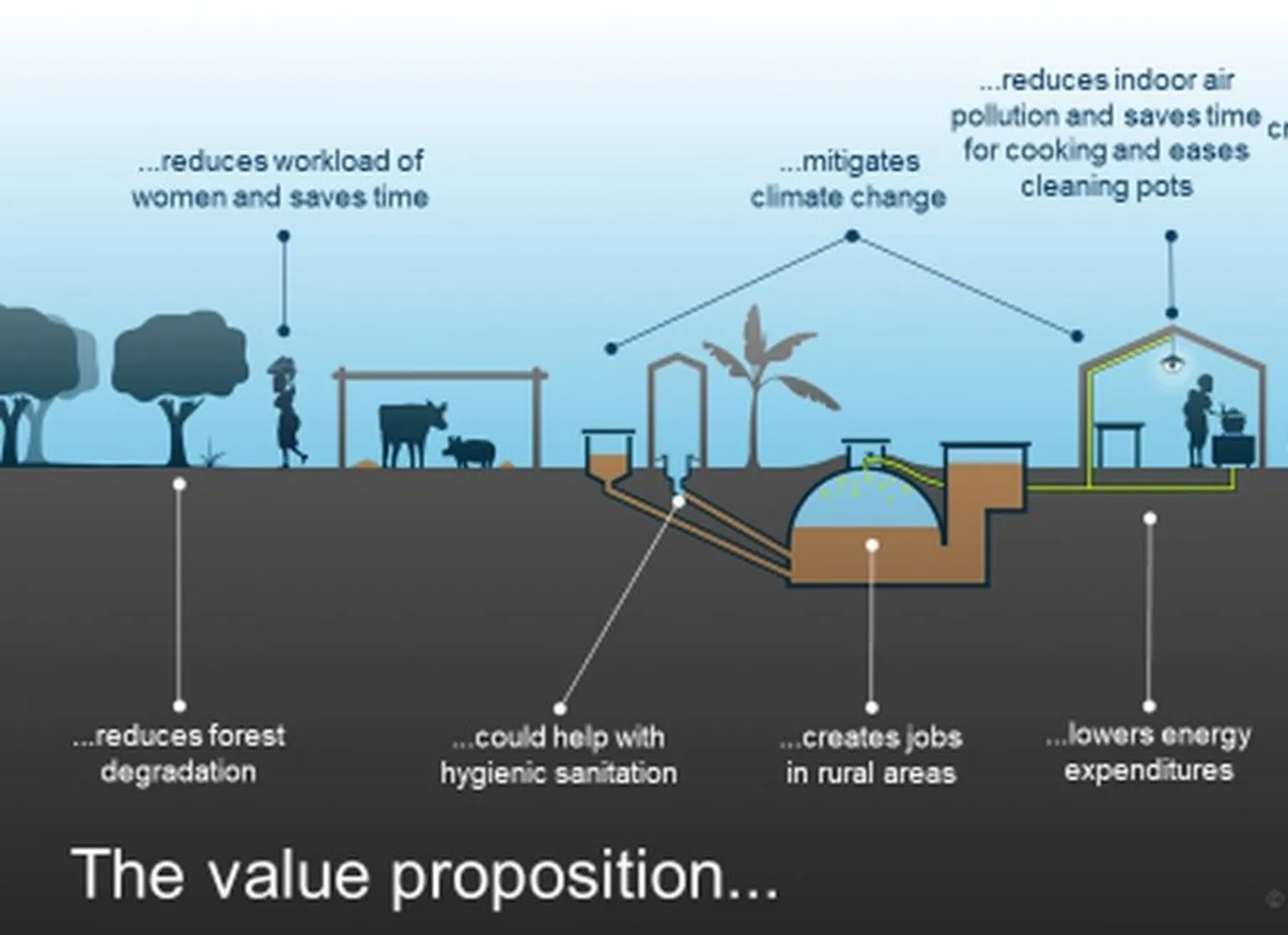

Bio-slurry, the process residue, can be used as a potent organic fertiliser to enhance agricultural productivity and sustain soil fertility. Crops assimilate the nutrients in bio-slurry thus increasing productivity on average by 25%.

Bio-digesters are of particular interest to smallholder dairy farmers. These farmers practice integrated farming, combining tillage with livestock keeping – an endless source of dung to be digested. To get a better overview of how biogas is produced have a look at the following short animation.

EPISODE ONE; IGNITING MARKETS

SNV’s work in biogas is long-standing, so what is your experience as to how markets develop after our projects close?

Till date, the direct impact of our programmes has been the installation of over 800,000 bio-digesters worldwide. Even though we are no longer directly involved in all the countries we once engaged with, we do see that many biogas markets are still thriving – which is not surprising, as the potential is enormous.

We started working in the biogas sector in the late nineteen-eighties in Nepal and since then expanded our reach to over 20 countries. The Nepali biodigester market has gradually matured, strongly supported by the Nepali government, while the construction and installation of digesters are now fully commercialised. The same holds for Vietnam where biodigesters are mostly fed with pig waste. But other countries still have a long way to go, developing markets is a matter for the long haul.

We expanded our activities to Africa in 2009, when we started the Africa Biogas Partnership Programme. To date, we have supported the installation of more than 60,000 digesters in five African countries. Uptake was not as fast as in Asia, due to the lower level of income and the prevalence of zero grazing (when cows roam around freely it is hard to collect the dung). However, current dynamics are promising. The Kenyan market is vibrant, sales this year has already doubled compared to last year, partially because companies have now introduced prefab digesters onto the market. Also, biodigesters are becoming more and more acknowledged as climate-smart solutions - cutting back on emissions, which is why the governments of Ethiopia and Burkina Faso are strongly supporting market growth.

What does SNV bring to the table when it comes to biogas?

SNV has built up a solid track record in kickstarting biodigester markets in developing countries. An important point is that we put a clear value proposition on the table, starting with solid business cases for farm households, biogas business enterprises and (M)FIs. Why should a farming household invest in a digester that costs an awful lot of money? They need to pay around 600 dollars upfront, but if one looks at the cost from an economic perspective, a digester is a good investment. Payback time is generally about two to three years.

What are the benefits that generate this positive business case?

Farmers save the money usually spent on buying firewood, charcoal or kerosene. People used to spend time collecting it for free, but governments increasingly prohibit this, or the area where they live is simply depleted. Fuel can cost up to one dollar a day. Instead, a bio-digester provides 3 to 4 hours of gas in your kitchen every day.

On top of that, the slurry can provide organic fertiliser. Chemical fertilisers are expensive and not always readily available. Depending on the specific crop and condition of the soil, the composted slurry can raise production by 10% - 50% compared to not using anything.

The business case is clearly positive, what is inhibiting the market in Africa?

Two buying barriers make potential buyers hesitant:

Three years ago up to 30% of biodigesters would not be working properly – even though in most cases that was due to the farmers’ behavior, not to any technical fault.

Most farmers don’t have ready cash available for the upfront investment, and interest rates on loans are high.

That sounds like a no-go

That’s where ABPP came in. We started an after sales programme to improve the quality of the installations. Farmers must be able to trust that their money is spent wisely.

We contracted a tech company with both call centre and data analysis services. The company calls farmers who bought a biodigester from enterprises supported by our programme. The ICT solutions have helped us tremendously. First of all, we use a mobile app to register all biodigesters timely and accurately, and put these in a database. This database triggers the calling. The call agent works on a script to check whether the digester has been delivered as promised. If the digester is not functioning properly we send out the supplier again – often to train farmers how to properly ‘feed’ the digester. We continue to follow up. Our database shows exactly how many digesters are functioning properly, even as time goes by.

Secondly, these calls enable us to build an online track record of suppliers. We have an incentive related to their after sales services because we want suppliers to build lasting relations with their customers.

We are now rolling out this programme to all countries with active biogas programmes.

And did you succeed in raising the quality?

We are getting there, according the latest user surveys the functionality rate for Burkina Faso is at 94%, while Ethiopia is at 77%, Uganda at 85% and Kenya at 88%.

Over to barrier two, how are you tackling the upfront investment costs in biogas?

After quality assurance, that is our next priority. We are setting up an investment facility that will provide farmers with affordable access to credit. In Asia financial institutions often stepped in, but in Africa investors still, perceive the biogas business as risky.

We have seen examples of farmers who have three heads of cattle and live on a few dollars a day getting a loan. For example from the savings and credit (SACCO) organisation linked to their dairy cooperative. The cooperative will take a percentage from their milk revenues to pay off the loan. We need to scale and de-risk these kinds of lending facilities. Therefore we are working on an investment facility to be financed with a blend of impact and public capital. The latter accepts zero returns, which reduces the overall interest rate or allows for longer-term loans. The share of public funding also provides subordinate capital that acts as a buffer for loss-making.

The investment facility will be an intermediate party that bundles smaller loans to biogas suppliers, microfinance institutions and SACCO’s. The facility will derisk impact investors, not only financially but also operationally with support from ABPP in doing periodic due diligence assessments of retail loan providers. The facility will start modestly, but we anticipate that it will increase confidence, and attract larger sums of money.

Can you tell a bit more about the supply side of biogas?

As I said, we started with a business case for all parties involved and helped them formulate a clear value proposition. Most of them are local entrepreneurs that lack the capital to invest, yet they need to travel and promote biogas. We pay them for their results. A payment that decreases gradually over time. In fact, we now use this incentive scheme to kickstart solar markets as well.

We also provide technical training to masons on constructing quality brick-dome digesters. And we showed SACCOS and dairy cooperations how biogas could benefit them. We convinced governments that quality standards are essential to creating confidence in the market. Our value is that we brought all these parties together to create a platform to cooperate, and will continue to do so in the long run